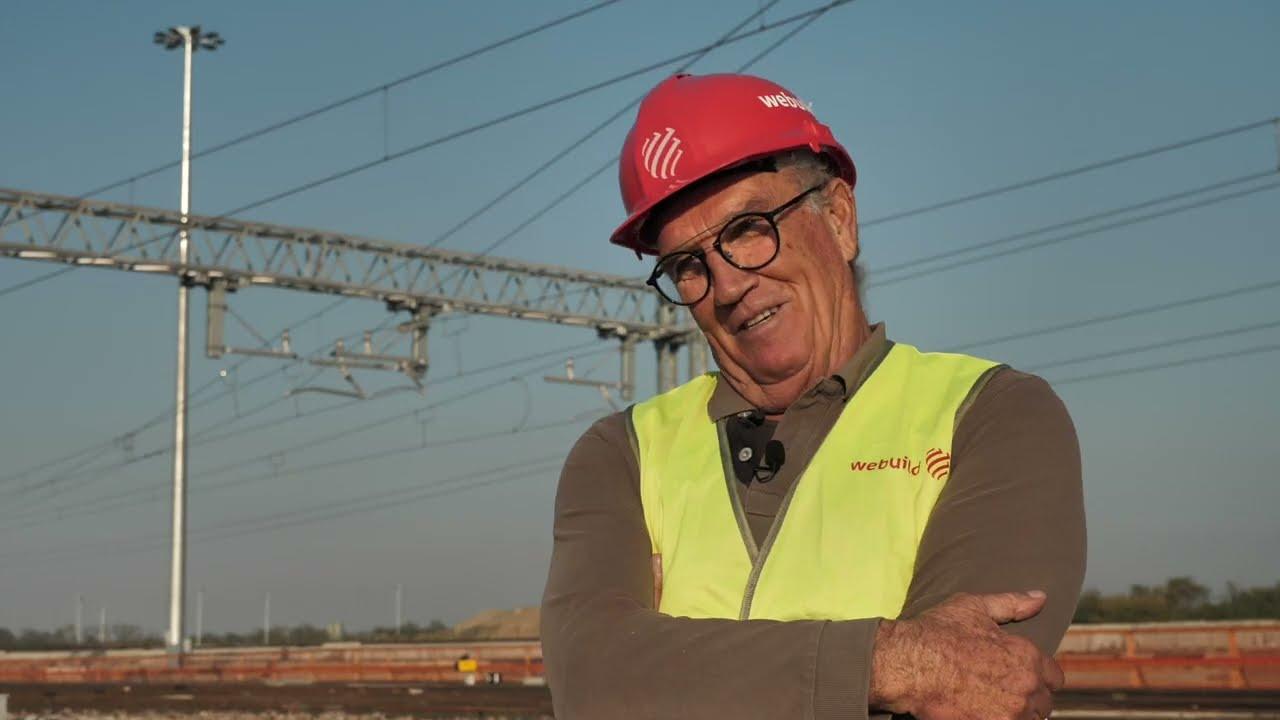

Pensa in grande. CANTIERE LAVORO ITALIA

The Webuild programme for training and hiring operators, technicians and professionals in the large infrastructure sector

With CANTIERE LAVORO ITALIA we train premium resources to make Italy even greater!

CANTIERE LAVORO ITALIA is the Group's new "industrialized training" and employment programme for thousands of young men and women and unemployed people to enter the large infrastructure construction sector. An all-Italian premium training hub to attract new resources from schools and the market, train the most sought-after technical profiles, and raise standards and know-how in the world of major construction works.

Infrastructure in Italy is expected to grow exponentially in the forthcoming years, which will make specialized training increasingly central to meeting the increased need for resources that are difficult to find on the market today.

To address this need, , Webuild has launched CANTIERE LAVORO ITALIA aimed at attracting new resources to the industry and ensuring its professional quality. Programme was launched in Belpasso (Catania, in the south of Italy) in Sicily. Region of Sicily and the Region of Calabria sign memorandums of understanding to promote employment, professional training and pre-work training

In May 2024, the programme was extended to Campania with training activities taking off at the Advanced Training Centre of the construction site.

CANTIERE LAVORO ITALIA: a project for Italy's future

Pensa in grande. Cantiere Lavoro Italia

The premium training and recruitment programme

With CANTIERE LAVORO ITALIA, various professional figures are trained and then hired by Webuild, both skilled labourers (including excavator miners, electricians, plant engineers...) and staff figures (including buyers, project accountants, TBM engineers).

The programme is open to young people with the first 3 years of secondary schooling (Terza Media in Italy) and/or high school diplomas, new university graduates, and anyone currently unemployed and wishing to undertake retraining and outplacement.

The programme's ambition is to build the next generation class of workers in the industry by transferring exclusive know-how to them, with professionalizing paths that connect classroom training with on-the-job training.

Cantiere Lavoro Italia develops pathways for different skills, with a focus on experiential training, on-the-job or on-the-job training, and soft skills and safety training, which are essential to be able to work on the construction site and raise quality standards in the industry.

The training model for the skills of the future

Cantiere Lavoro Italia, hiring and training programme of Webuild, inforaphic

Cantiere Lavoro Italia, from training to a TBM's cockpit

Videonews: Cantiere Lavoro Italia, Webuild - Il lancio del programma

Videonews Cantiere Lavoro Italia, Webuild per il Sud

Cantiere Lavoro Italia. I Giovani di Sicilia e Calabria nel programma di Webuild

The 3 practical "CANTIERE LAVORO ITALIA" schools

A Premium Educational Network

The CANTIERE LAVORO ITALIA programme consists of 3 Schools aimed at new resources, plus a school for internal profiles for ongoing training, for Group resources. The 3 schools aimed at external targets adopt a two-stage system: general basic pre-employment training - in collaboration with Italy's leading Employment Agencies - and an in-house recruitment with an "on-the-job" specialization paths for staff figures, and in Advanced Practical Training Centres for blue-collar workers.

Territorial school

Young people and the unemployed are trained here, with the goal of training tomorrow's Webuild professionals, both blue and white collar ones, with specific pathways according to the type of role. The school operates in cooperation with employment agencies and training institutions throughout Italy, and in partnership with institutions, universities, municipalities, labour unions, and construction schools

Trade School

Genuine training aimed at employment, with hands-on, on-the-job training for labourers and technical specialists. This is the school dedicated to training for contract work, with the use of machinery and simulators that will allow you to recreate construction site conditions and activities. It consists of training centres that at full capacity allow to train about 900 resources/year like excavator miners, carpenters, surveyors, TBM operators, mechanics, and electricians.

Professions School

Post-hire training for professionals, in the classroom and on site, to ensure the most advanced skills for staff figures (technical, project management figures in areas such as buying, BIM, construction accounting, TBM machine engineering). Three Advanced Training Centres are planned to be activated: the first, at the Novi Ligure site for the Terzo Valico dei Giovi project dedicated to traditional excavation and open work; a second in Sicily; and a third in Campania for mechanized excavation.

Italy: a nation filled with many stories

Stories that tell of a large family that shares a passion for building and the satisfaction of looking back and seeing what has been since accomplished

Stories: le persone dentro e fuori i cantieri. L'Italia è un paese di storie

Roboplant: factories of the future

Pre-cast Concrete Segment Factories 4.0

The first of its kind in Italy, Roboplants are automated, safe, and environmentally friendly factories to produce pre-cast concrete segments, the structures with which freshly excavated tunnel walls are lined in tunnels of major infrastructure works such as railways or metros.